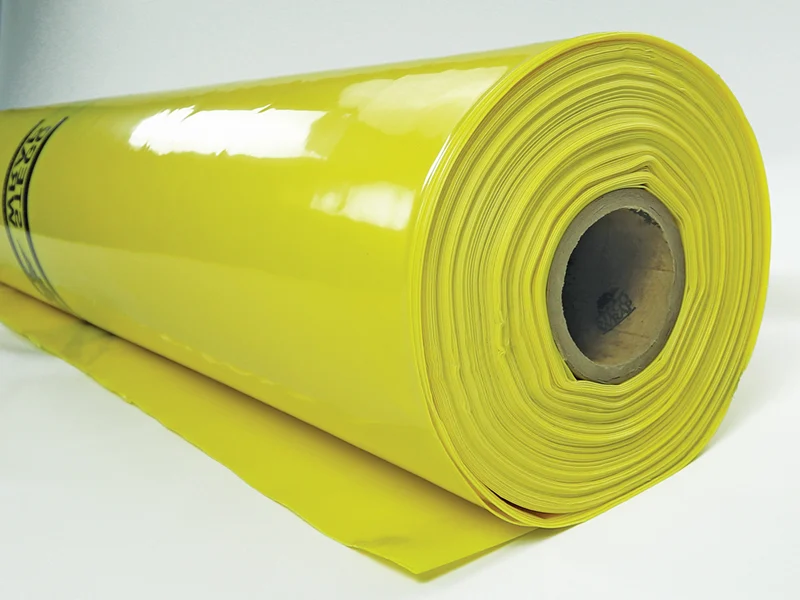

USES: Stego Wrap Class A is used as an exceptional vapor retarder.

COMPOSITION: Stego Wrap Class A is a multi-layer plastic extrusion manufactured with only high grade prime, virgin,

polyolefin resins.

ENVIRONMENTAL FACTORS: Stego Wrap Class A can be used in systems for the control of soil gases (radon, methane),

soil poisons (oil by-products) and sulfates.

4. TECHNICAL DATA

TABLE 1: PHYSICAL PROPERTIES OF STEGO WRAP 10-MIL CLASS A VAPOR RETARDER

PROPERTY TEST RESULTS

Under Slab Vapor Retarders ASTM E1745 Class A, B & C – Standard Specification for Water Vapor Retarders

Used in Contact with Soil or Granular Fill under Concrete Slabs Exceeds Class A, B & C

Water Vapor Permeance ASTM F1249 – Test Method for Water Vapor Transmission Rate Through Plastic

Film and Sheeting Using a Modulated Infrared Sensor 0.0254 perms

Permeance After Conditioning ASTM E154 Section 8, F1249 – Permeance after wetting, drying, and soaking 0.0258 perms

(ASTM E1745 ASTM E154 Section 11, F1249 – Permeance after heat conditioning 0.0259 perms

Sections 7.1.2 - 7.1.5) ASTM E154 Section 12, F1249 – Permeance after low temperature conditioning 0.0241 perms

ASTM E154 Section 13, F1249 – Permeance after soil organism exposure 0.0245 perms

Puncture Resistance ASTM D1709 – Test Method for Impact Resistance of Plastic Film by

Free-Falling Dart Method 3,006 grams

Tensile Strength ASTM D882 – Test Method for Tensile Properties of Thin Plastic Sheeting 50.6 lbf/in

Thickness 10 mil

Roll Dimensions width x length: 14' x 210'

area: 2,940 ft2

Roll Weight 140 lb

Note: perm unit = grains/(ft2*hr*in-Hg)

STEGO® WRAP 10-MIL CLASS A VAPOR RETARDER

A STEGO INDUSTRIES, LLC INNOVATION | VAPOR RETARDERS 07 26 00, 03 30 00 | VERSION: MAR 3, 2022

DATA SHEETS ARE SUBJECT TO CHANGE. FOR MOST CURRENT VERSION, VISIT STEGOINDUSTRIES.COM

(877) 464-7834 | stegoindustries.com

All designated trademarks are the intellectual property of Stego Industries, LLC. Installation, Warranty, and State Approval Information: stegoindustries.com/legal.

©2022 Stego Industries, LLC. All rights reserved.

P2 OF 2

5. INSTALLATION

UNDER SLAB: Unroll Stego Wrap Class A over an aggregate, sand or tamped earth base. Overlap all seams a minimum

of 6 inches and tape using Stego® Tape or Stego® Crete Claw® Tape. All penetrations must be sealed using a combination

Additional information

| Brand | STEGO |

|---|