Roadware Concrete Mender

ROADWARE 10 MINUTE CONCRETE MENDER™

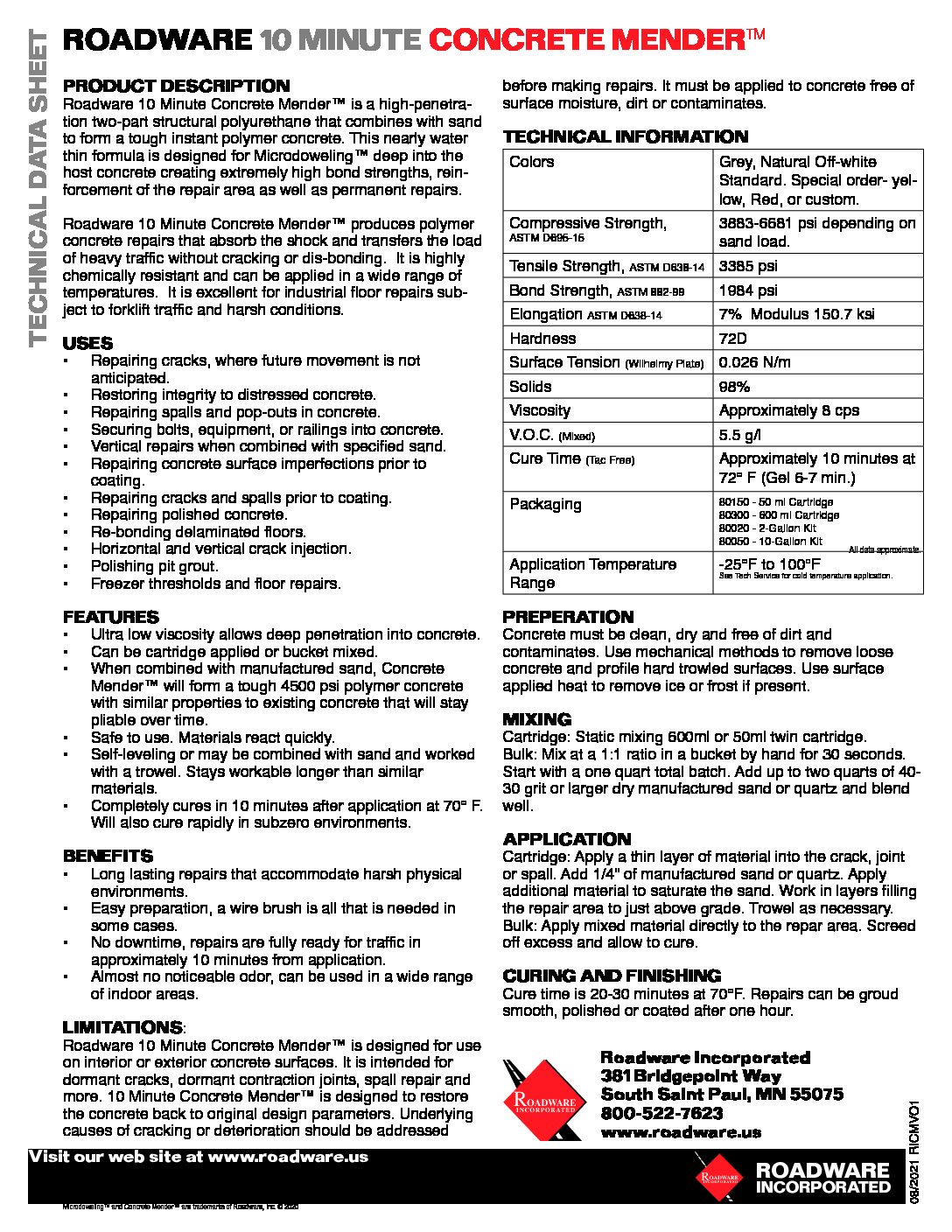

Now you can repair cracks and spalls to a smooth finish in a fraction of the time it takes with ordinary products. Roadware 10 Minute Concrete Mender is a revolutionary new two-part hybrid urethane for repairing concrete. It’s nearly water thin for deep penetration and it won’t pop out like epoxy because it never gets bri

Cures in just 10 minutes at 70°F (21°C) • Works in freezers below -20°F (-28°C) • May be polished • Never gets brittle • Easily applied • Contains no epoxy or polyurea • Easy to mix • Nonflammable • Low V.O.C’s • Paintable • Coatable • Sandable • Meets USDA guidelines • And more…

80300-cartSelf-mixing at point of application.

Use a standard 1:1 ratio 600ml cartridge application gun. See Cartridge Application Instructions.

needleNeedle tip mixes are available.

For precise application. Choose from 14, 15 or 18 gauge.

Full depth crack injection without pumps or ports. Easy to use Sift-tip injection mixers make full depth crack injection possible.

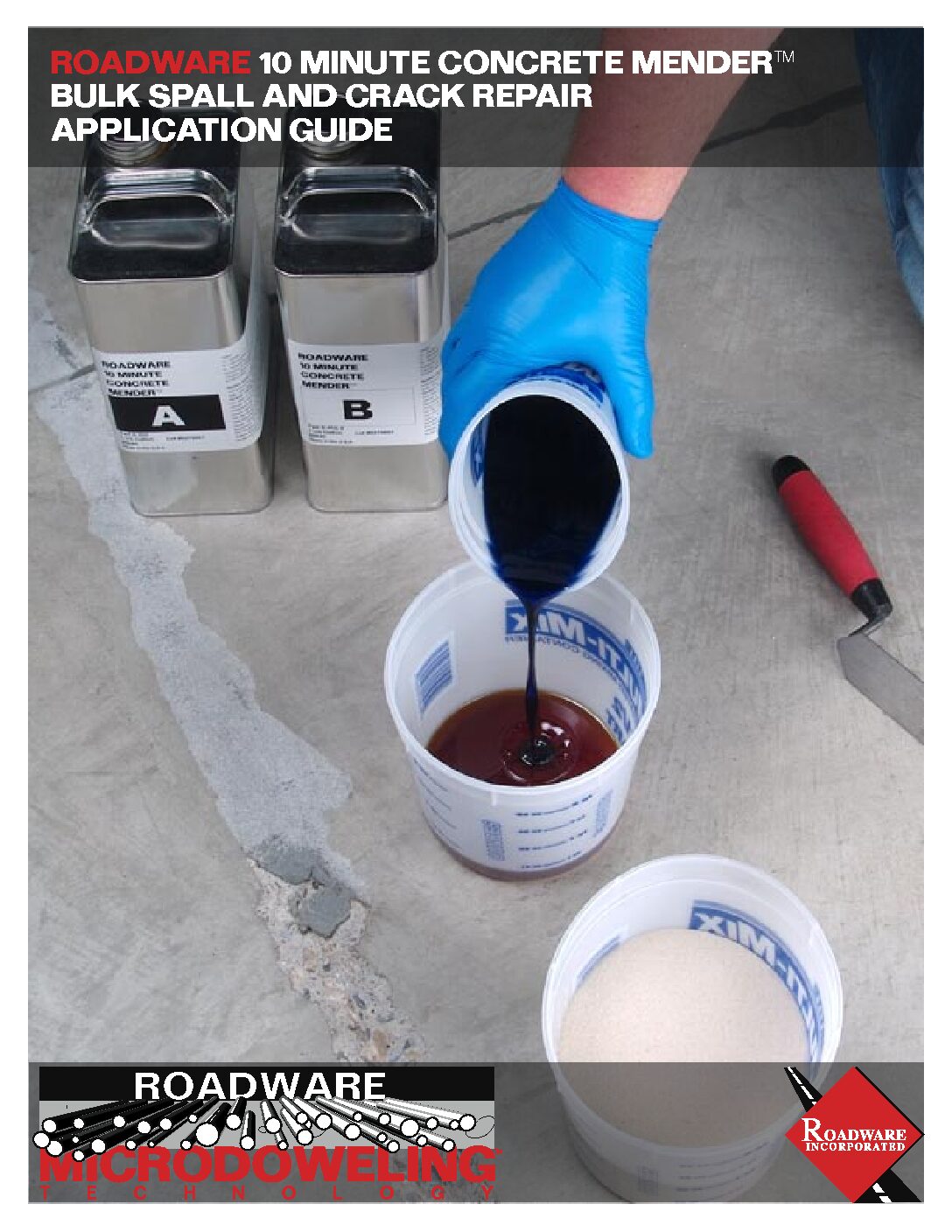

pourBulk mix application for larger cracks and spalls. Available in one gallon containers, two-gallon kits. Simply add sand and mix by hand. Also available in ten-gallon kits.

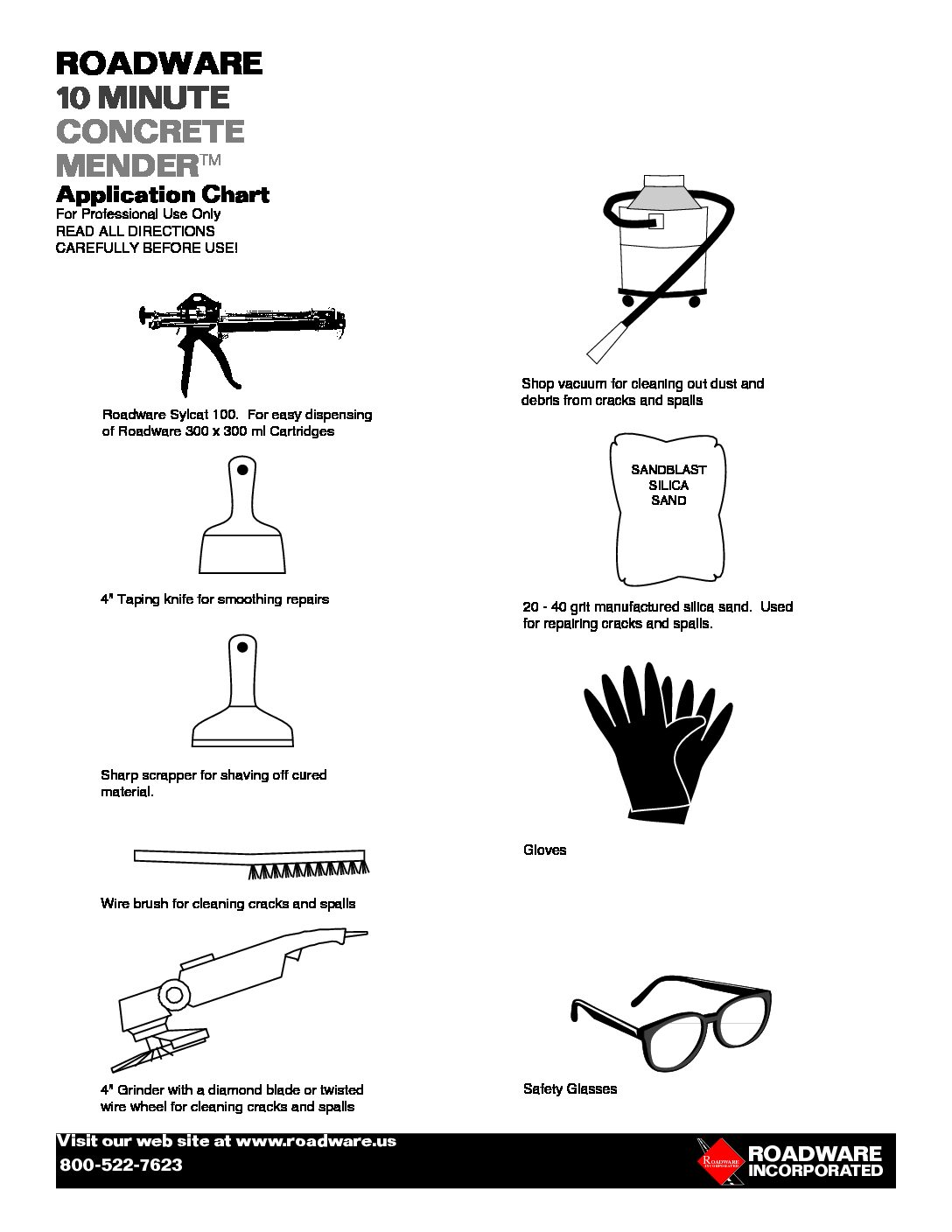

chartExtend with sand.

One gallon of Concrete Mender™ makes about 2.2 gallons of repair material when combined with 2 parts silica sand. 2X the yield of epoxy or polyurea. See our Product Estimator.

freezerFreezer Floors

Repair concrete at working freezer temperatures below -20°F (-28°C).

grindGrind, polish and coat. Accepts polishing or most coating systems in about 10 minutes at 70°F (21°C)

Features/Benefits

Advantages– Due to the very low surface tension of the material and low viscosity, complete saturation bonding of cracks can be easily achieved. Minimal prep to remove loose debris is all that is normally required. This can be considered a structural repair if the material is allowed to gravity flow to the full depth of the crack. Manufactured sand or quartz may be introduced into the repair as necessary to prevent under slab ponding and material waste. For repair greater than 0.125 inches, specified sand may be added at a ratio of two parts sand to one part mixed polyurethane as the crack is filled to extend the material and add strength. The sand also brings the thermal coefficient of expansion of the repair material closer in-line with surrounding concrete. Polyurethanes of this nature may be applied in a wide range to sub-straight temperatures making them useful in frozen and cold storage warehouse applications or cold weather application below -20F (-23C). Repairs are typically ready to accept traffic in approximately 10 minutes at 72F (22C)

Technical Information

Structural Polyurethane– A polyurethane based material that restores structural integrity and aggregate interlock to distressed concrete by using low surface tension and low viscosity to penetrate concrete surfaces and cross -linking polymer chains to bond directly to the concrete-aggregate matrix. This bonding action utilizes capillary forces to self-inject polymer chains into the surrounding concrete. This material should have a modulus of elasticity less than the surrounding concrete and should not become brittle over time. This material may be combined with manufactured sand to form a PCC compatible polymer concrete that can structurally repair concrete cracks and spalls.

Additional information

| Sizes Available | 2 Gal.unit, 21 oz Hand Kit, 5 Gallon Unit |

|---|